-

OUTDOOR LED DISPLAY

OUTDOOR LED DISPLAY

-

INDOOR LED DISPLAY

INDOOR LED DISPLAY

-

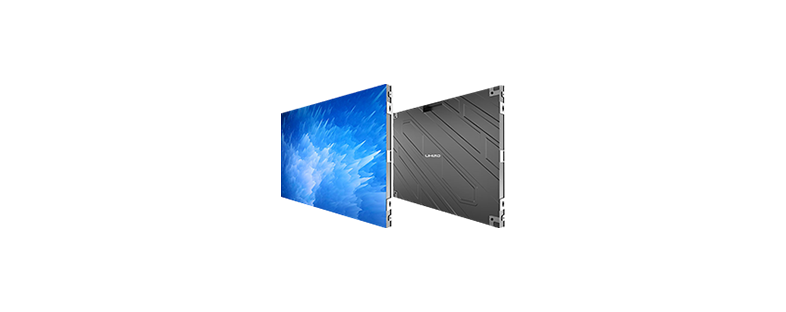

RENTAL LED DISPLAY

RENTAL LED DISPLAY

-

SHELF LED DISPLAY

SHELF LED DISPLAY

-

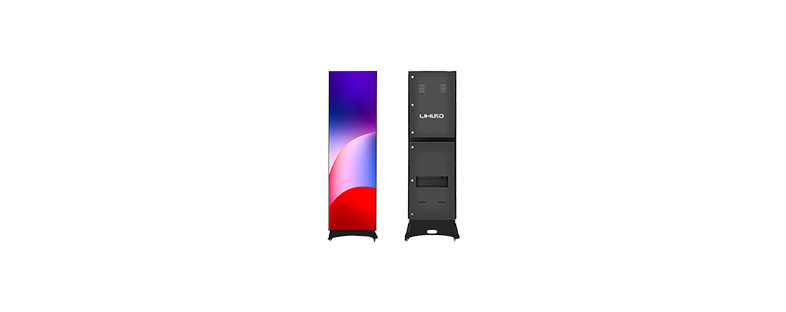

POSTER LED DISPLAY

POSTER LED DISPLAY

-

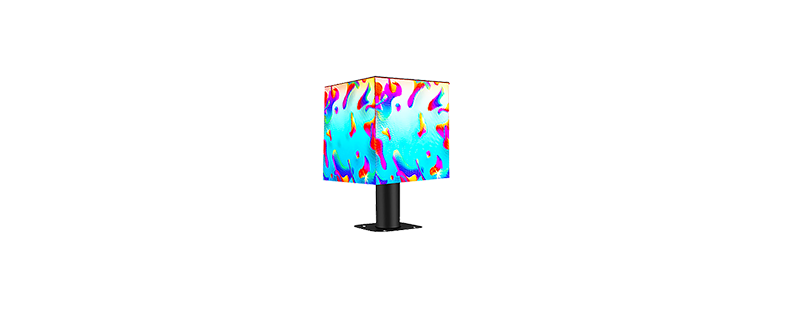

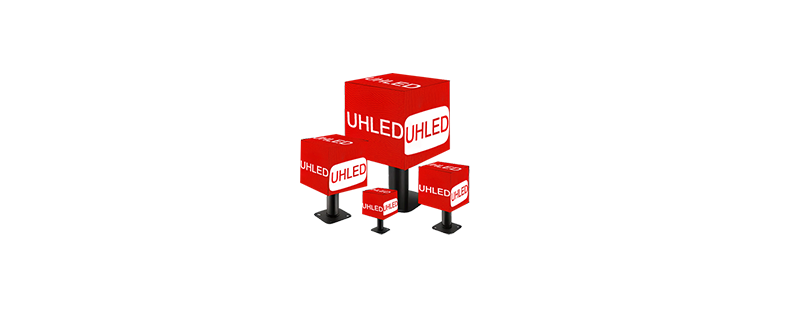

CUBE LED DISPLAY

CUBE LED DISPLAY

-

FLEXIBLE LED FILM

FLEXIBLE LED FILM

- TRANSPARENT LED DISPLAY

COB vs GOB in LED Display: Technical Differences and Scenario Adaptation Guide

In the context of the rapid iteration of LED display technology, COB (Chip on Board) and GOB (Glue on Board), as two mainstream packaging technologies, are often used to improve the reliability and display effect of displays. This article will conduct a comparative analysis from the perspectives of technical principles, core performance, and application scenarios, providing clear selection references for industry customers.

Technical Principles: Essential Differences in Packaging Processes

COB technology adopts a “chip-level integration” solution, directly bonding and wiring LED chips on a PCB board to form an integrated module without brackets. Its core is to eliminate the bracket gaps of traditional SMD lamp beads through multi-chip integrated packaging (usually integrating thousands of chips in a single module), and achieve high-contrast display with black packaging glue.

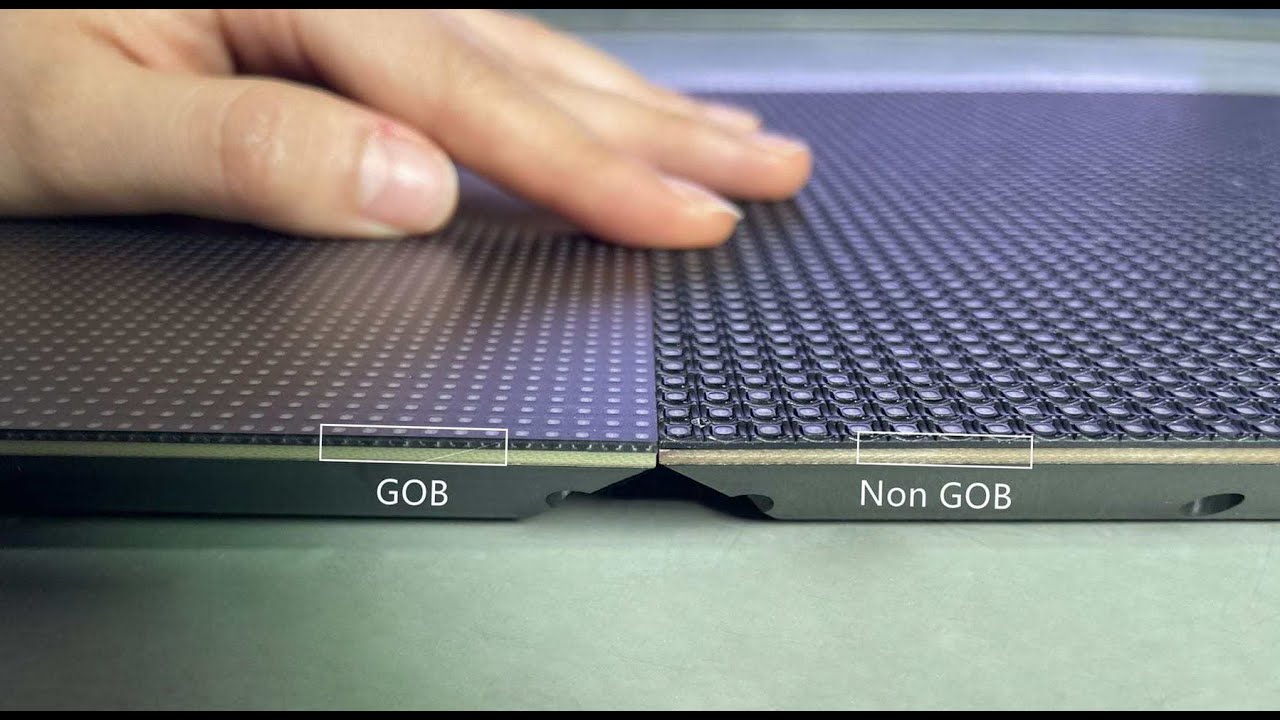

GOB technology covers the surface of traditional SMD lamp beads with a layer of high-transparency epoxy resin glue (0.3-0.5mm thick), and completely wraps the lamp beads and PCB board through a glue pouring process. After high-temperature curing, the glue layer forms a protective barrier and fills the gaps between lamp beads to reduce light reflection. This technology is compatible with existing SMD production lines, and the transformation cost is only 1/5 of that of COB.

Core Performance Comparison: Comprehensive Analysis from Protection to Display

1. Protection Performance: GOB Focuses on Physical Protection, COB Considers Environmental Adaptation

- GOB: The glue layer directly covers the surface of lamp beads, achieving IP65 dust and water resistance. The impact resistance is increased to 10kg/cm² (traditional SMD is only 3kg/cm²), which can effectively resist dust, liquid splashing, and slight collisions, especially suitable for dusty scenes such as bars and children’s playgrounds.

- COB: Achieves IP54 protection through integrated packaging. Although its waterproof performance is slightly inferior to GOB, its wide operating temperature range of -40℃ to 80℃ (GOB is -20℃ to 60℃) makes it more suitable for outdoor low-temperature or high-temperature environments.

2. Display Effect: COB Excels in Delicacy

- Resolution and Contrast: Due to the absence of lamp bead brackets, COB can easily achieve a pixel density of over 10000PPI (such as P0.4 products) with a contrast ratio of 10000:1; limited by the size of SMD lamp beads, GOB has a maximum pixel density of about 4000PPI (P1.0) and a contrast ratio of 8000:1.

- Viewing Angle Performance: COB uses full-angle light-emitting chips with horizontal/vertical viewing angles of 178°; GOB has an edge viewing angle brightness attenuation of about 15% due to the influence of glue layer refraction.

3. Reliability and Lifespan: COB is More Suitable for Long-Term Operation

- Heat Dissipation Capacity: COB chips are in direct contact with the PCB board, with a thermal resistance as low as 3℃/W (GOB is 8℃/W). After 5000 hours of continuous operation, the brightness attenuation rate is only 5% (GOB is 12%).

- Fault Maintenance: Damaged GOB single lamp beads can be replaced individually with a maintenance cost of about 5 yuan per point; COB requires overall module replacement with higher maintenance costs , but due to high integration, the failure rate is only 1/3 of that of GOB.

Application Scenarios: Technical Characteristics Determine Scenario Adaptability

Advantageous Scenarios for COB Technology

- High-End Indoor Display: Such as command centers (P0.6-P1.2) and 4K conference rooms (P1.5-P2.0), which require high resolution and long lifespan guarantee.

- Low-Temperature Outdoor Environment: Outdoor large screens in regions such as Northern Europe, where the wide temperature characteristics can reduce winter failures.

- Close-Range Viewing Scenarios: Museum showcase screens (viewing distance < 1m), with delicate image quality to avoid graininess.

Advantageous Scenarios for GOB Technology

- Entertainment Venues: with impact resistance and dustproof performance to reduce maintenance frequency.

- Humid Environments: Information screens in swimming pools and hot spring areas, with IP65 protection to resist water vapor erosion.

- Budget-Sensitive Projects: Advertising screens in small and medium-sized supermarkets, with low transformation costs and meeting basic protection needs.

Market Trends and Selection Suggestions

Technical Iteration Direction

- COB is upgrading to Micro COB, with the yield rate of products below P0.3 reaching 85%, and the cost is expected to decrease by 30% in 2025.

- GOB is developing towards flexible glue layers, which can achieve 30° bending, adapting to special-shaped scenarios such as curved stage screens.

Selection Decision Tree

- If the project requires ultra-high definition below P1.0 + long lifespan→ COB is preferred.

- If high protection + low cost + easy maintenanceis needed → GOB is preferred.

- For outdoor low-temperature scenarios → COB must be selected; for humid and dusty indoor environments → GOB is preferred.

Conclusion: There is No Absolute Superiority or Inferiority in Technology, and Adapting to Scenarios is the Core

COB and GOB are not alternative,but optimized choices of LED display technology in different demand scenarios. As a leading display solution provider in the industry, we can provide customized technical solutions according to your project parameters (resolution, environment, budget, etc.). Welcome to contact us to obtain an exclusive evaluation report.