-

DISPLAÇÃO DE LEADA DE FORA

DISPLAÇÃO DE LEADA DE FORA

-

DISPLAÇÃO DE LED INDOR

DISPLAÇÃO DE LED INDOR

-

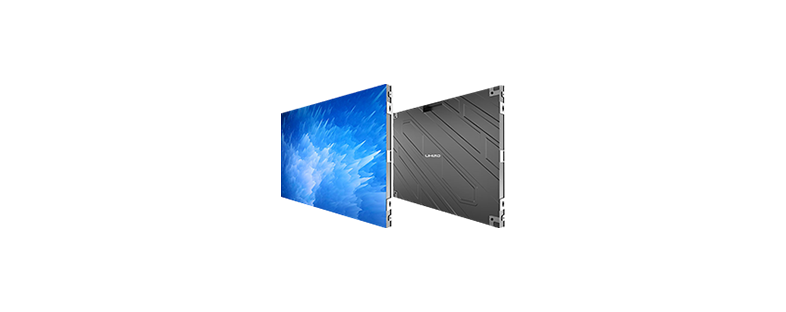

DISPLAÇÃO DE LEDA RENTAL

DISPLAÇÃO DE LEDA RENTAL

-

A SHELF LED DISPLAY

A SHELF LED DISPLAY

-

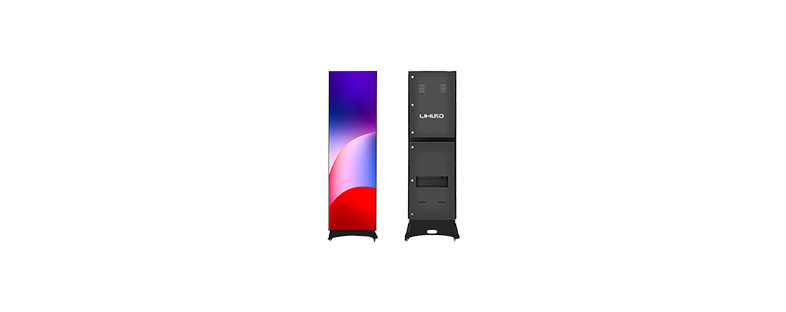

DISPLAY POSTER LED

DISPLAY POSTER LED

-

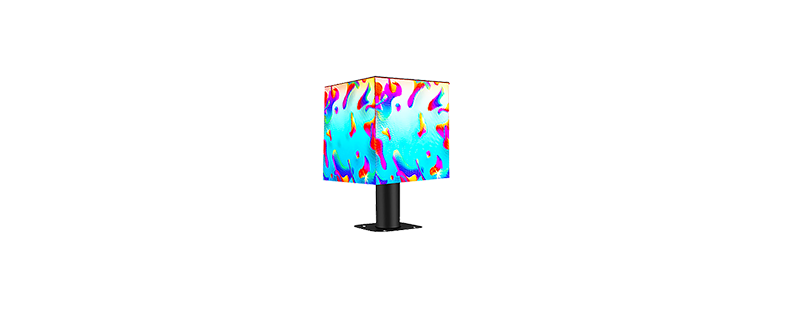

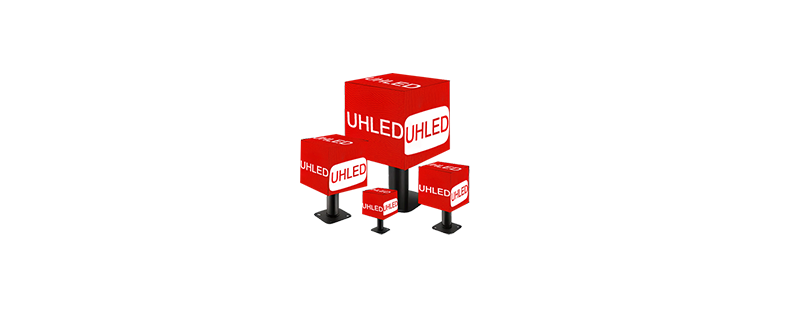

DISPLAY CUBE LED

DISPLAY CUBE LED

-

FILMA FLEXIBLE LED

FILMA FLEXIBLE LED

- DISPLAÇÃO TRANSPARENTE DE LED

Clearer Images, Longer Lifespan: The Real Advantage of COB Indoor LED Displays

In the current B2B market, indoor LED displays need to handle more than just bright images. They must work steadily in demanding operational environments. They also have to keep sharp pictures over time. Plus, they should allow easy upkeep without high costs. Uses like corporate lobbies, retail stores, conference rooms, and control rooms demand screens that can run for extended periods. These screens face challenges such as dust accumulation, potential physical contact, and the need for consistent visual performance. For years, surface-mounted device (SMD) and glue-on-board (GOB) methods have driven most indoor LED setups. Yet, these days, they often fail to deliver solid stability, tight pixel spacing, or the robust build quality required for high-end applications.

Limitations of Traditional SMD and GOB Technologies

SMD tech provides good growth options and fair picture quality. However, it depends on fragile wire bonding and exposed LED packages. These parts can be susceptible to damage from accidental impact or environmental contaminants. GOB adds safety by covering parts in a resin coat. But this can bring extra steps and bulk, which may influence heat dissipation. Moreover, potential issues with colloidal properties and difficult on-site repair can arise. Both approaches can struggle with achieving ultra-fine pixel gaps and maintaining pristine performance over long periods in intensive use.

What is COB Technology?

COB means Chip-on-Board. In this method, several LED chips sit directly on one base. Then, a thin resin layer goes over them. SMD differs because each chip comes pre-wrapped and gets soldered one by one. COB joins many chips into one solid unit, skipping wire ties.

Comparison with SMD and GOB Technologies

COB skips wire bonds. This boosts structural strength, improves cooling, and enhances reliability. Such traits suit high-performance indoor applications well. GOB puts a resin shield over SMD units. COB offers superior thermal conductivity and a more streamlined, seamless profile compared to GOB.

Key Features of COB Packaging

A main plus for COB is its bond-wire-free architecture. There are no weak solder spots linking chips to the board. This cuts down on breakdowns from LED failure or solder joint fatigue. The even, flat face helps join modules smoothly without visible gaps, enabling a perfectly seamless display surface.

Advantages in Visual Performance

Higher Pixel Density and Fine Pitch Capability

COB places chips close together. This creates small gaps between pixels, or fine pitch. So, displays gain great detail even in compact forms, making them ideal for viewing at close distances. Think of corporate boardrooms where attendees sit nearby, or high-end retail led walls for immersive brand experiences. For example, in a real project at a corporate headquarters, our fine-pitch COB screen allows viewers to spot intricate details from just a few meters away without any blur. The pixel pitch (such as P1.2, P1.5, P1.8) refers to the distance between adjacent pixels. The smaller the pitch, the higher the resolution, which is essential for close viewing in indoor environments.

Enhanced Contrast and Color Uniformity

COB units feature an Ultra-high Contrast Ratio. The seamless surface effectively minimizes light reflection between pixels, building deeper contrast. You get richer blacks, vibrant colors, and exceptional uniformity all over the display. It holds up perfectly in brightly lit indoor environments, too. Take a sunlit atrium lobby installation: the COB screen keeps images crisp and colors true, unlike older types that can appear washed out.

Durability and Environmental Resistance

Superior Thermal Management Design

COB’s direct chip-to-board contact spreads heat efficiently. This ensures stable operation during long hours of use, prevents overheating, and significantly extends component lifespan. This reliability is crucial for control rooms or broadcast studios where displays must operate continuously without failure.

Robust Build for Demanding Environments

Without exposed wires or individual beads, COB avoids common failure points like loose connections or damage from dust ingress. The firm resin surface is also more resistant to scratches and minor impacts. That’s key for high-traffic areas like museums, showrooms, or transportation hubs where screens might be subject to accidental contact or cleaning.

Long-Term Reliability for B2B Applications

Stable Optical Performance Over Time

COB screens show less fade in brightness and color after years of daily use. The uniform encapsulation protects the chips from dust oxidation and other environmental factors that can degrade traditional units. Picture a 24/7 financial trading desk screen running for years; COB technology helps maintain consistent luminance and color accuracy, while others may visibly dim and shift over time.

Lower Maintenance Costs and Downtime Risks

With a more integrated design and fewer failure-prone components, reliability is inherently higher. This translates to significantly reduced maintenance needs. We provide free remote technical support, and should module replacement ever be necessary, the process is straightforward. UHLED offers convenient maintenance-friendly cabinet designs. So, any required service can happen quickly with minimal disruption. This drastically cuts potential downtime and associated costs, protecting your operational continuity.

UHLED’s Commitment to COB Innovation

Brief Overview of UHLED’s Product Lineup

Em UHLED, we focus on high-performance indoor LED display solutions for professional and commercial use. Our company’s main products include fine-pitch indoor LED HD displays, rental screens, creative led walls, LED posters, transparent screens, irregular shape screens, and displays for various scene applications. We have strong pre-sales solution design and after-sales service technical support, with a team of project engineers who can provide comprehensive support. Our dedication to innovation is evidenced by our full adoption of COB technology in our premium indoor product lines, which has dramatically enhanced reliability based on client feedback.

Focus on Quality, Longevity, and Customization Options

UHLED stands behind the durability of our COB displays. We offer a comprehensive warranty and committed after-sales support. We provide 24-hour technical response, professional installation guidance, and full customization of dimensions, shapes, and cabinet types to fit your specific project needs seamlessly. Whether you need a vast, curved led wall for a brand flagship store or an ultra-high-resolution display for a broadcast studio, we can tailor a COB-based solution for flawless integration and enduring performance.

Conclusion: Why COB is the Future for High-End Indoor LED Displays

COB technology delivers substantial value for indoor applications. It brings superior reliability, enables ultra-fine pixel pitches, delivers outstanding visual quality, and reduces long-term maintenance burdens—making it ideal for demanding B2B and commercial indoor installations. At UHLED, we integrate this advanced technology into our displays to offer exceptional durability while ensuring a visually seamless and stunning image. COB eliminates wire bonding, improving durability, heat dissipation, and overall stability—ideal for critical indoor environments where performance cannot be compromised..

FAQ

Q: What makes COB technology better than for high-end indoor use?

A: COB eliminates fragile wire bonding, improving structural durability, heat dissipation, and reliability. Its seamless surface also provides better visual consistency and is easier to clean and maintain, which is ideal for controlled indoor environments where image quality and uptime are paramount.

Q: How does COB improve the clarity of an indoor LED display?

A: With higher pixel density, superior contrast ratios, and a perfectly seamless surface that eliminates gaps between modules, COB provides sharper, more immersive images with exceptional uniformity, even in well-lit rooms.

Q: Is the robust build of COB displays necessary for indoor settings?

A: Absolutely. In high-traffic commercial, corporate, or public spaces, displays can be subject to dust, cleaning, and accidental contact. COB’s integrated and protective design minimizes common failure points, ensuring reliable operation and reducing the risk of damage.

Q: Can COB displays reduce long-term maintenance costs for indoor installations?

A: Yes, significantly. Their robust, simplified design minimizes common failures. This leads to fewer service interventions, lower spare parts consumption, and less operational downtime, resulting in a lower total cost of ownership over the display’s lifespan.

Q: What indoor applications benefit most from fine pitch COB displays?

A: High-end applications such as corporate boardrooms and control rooms, broadcast studios, luxury retail led walls, museums and galleries, hospitality spaces, and any installation requiring close-viewing distances, flawless image quality, and maximum reliability benefit immensely from fine pitch COB technology.