GOB vs. COB LED Displays: How to Choose the Right Solution for Indoor and Outdoor Projects

GOB vs. COB LED Displays: How to Choose the Right Solution for Indoor and Outdoor Projects

Understanding LED Packaging Technologies

LED display technology continues to evolve rapidly, driven by increasing demands for higher resolution, durability, and reliability. The role of LED packaging grows clearer in shaping how well displays work, how long they last, and how easy they are to fix. This includes traditional Surface-Mounted Device (SMD) packaging methods as well as newer encapsulation technologies. Packaging shields the LED chip. It also affects light output, heat flow, and resistance to environmental exposure and mechanical stress.

In business-to-business setups, like big installs or key operations, two packaging types stand out—COB (Chip-on-Board) and GOB (Glue-on-Board). These differ a lot in build and how they perform. Each brings its own strengths, fitting different situations.

What is COB Technology

Definition and Working Principle

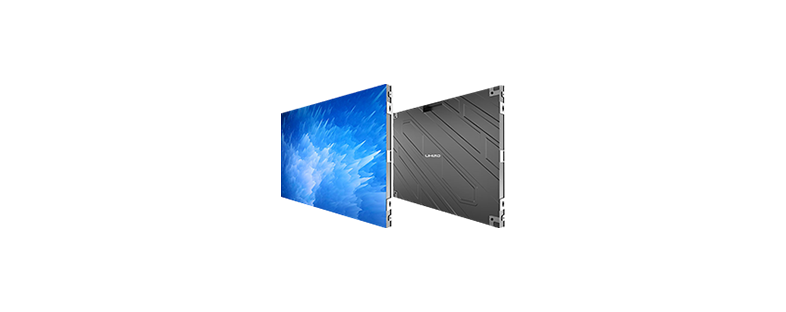

COB (Chip-on-Board) tech means placing several LED chips right on a printed circuit board (PCB) base. It skips the usual encapsulation packages. COB technology mounts multiple bare LED chips directly onto the PCB or substrate, typically using wire bonding or flip-chip processes, followed by an integrated encapsulation layer for protection and optical uniformity.

This close packing enables COB technology to achieve higher pixel density and superior image uniformity in fine-pitch LED displays. Without separate SMD parts, the gap between LEDs shrinks. As a result, you get smooth pictures even when people view from very near.

Key Features of COB

COB tech shines in top-tier indoor spots because of its main traits:

- High packing density for tight-pitch LED screens. This suits control rooms, TV studios, and fancy shops.

- Great heat release and power savings. The direct chip-to-board link cuts down heat buildup.

- Better dependability in premium uses. No solder points means less chance of breakdowns from heat shifts or physical strain.

What is GOB Technology

Definition and Working Principle

GOB (Glue-on-Board) tech applies a transparent epoxy encapsulation layer over conventional SMD LEDs after mounting them on the PCB. This glue acts as a shield. It guards against bumps and outside factors like water and dirt. GOB keeps the basic SMD setup. But it boosts toughness with that extra coat. This is particularly beneficial in rental applications involving frequent installation and dismantling.

Key Features of GOB

GOB tech fits rental screens and outside uses well, thanks to its sturdy build:

- Strong guard against hits, key for often-moved rental gear.

- Blocks water and dust, perfect for tough outdoor spots like rainy festivals.

- Affordable fix for rentals and outdoors. It adds toughness without hiking costs much.

GOB vs. COB: Core Technical Differences

Waterproofing and Moisture Resistance

GOB technology offers enhanced waterproofing performance due to its full encapsulation layer, often achieving higher IP ratings compared to standard SMD structures. The glue layer handles wet spots well. So, it’s reliable in places with rain or sea air, say along a busy harbor where displays face salt spray daily.

COB’s water resistance relies on its closed chip setup. It does fine in steady indoor air. But in wild weather, it has some limits. Still, the sealed design holds up in most controlled rooms.

Impact Resistance and Durability

GOB leads in handling bumps. Its soft glue soaks up shocks better. This makes it great for moving events, where screens get loaded and unloaded hundreds of times a year.

COB has a firm frame. That gives solid strength for steady spots. However, due to its integrated structure, COB displays may be less tolerant of severe mechanical impact and are generally more challenging to repair at the pixel level, like in a crowded trade show.

Heat Dissipation Performance

COB screens win big on heat control. The straight chip-to-board path lets heat escape fast. This stretches part of life and keeps steady work during long runs, such as 24-hour monitoring in a security center.

GOB units manage heat okay. They’re fine for quick events or on-off use. But in hot areas with constant power, they might struggle, like during summer outdoor markets.

Viewing Angle and Visual Performance

For key indoor views, COB gives broader sight lines with even colors from side to side. It’s perfect for TV setups or office hubs, where folks sit in rows and need clear sight from all seats.

The additional encapsulation layer in GOB may introduce slight optical diffusion, which can affect color consistency at extreme viewing angles. This might tweak the color match at sharp angles. In a retail window, though, it still looks sharp for passing crowds.

Choosing Between GOB and COB Based on Application Scenarios

Fine Pitch Indoor Displays (e.g., control rooms, studios)

In sharp indoor setups where clear images count most, COB takes the lead. It’s tight packing hits pitches like P1.875 or finer. UHLED’s fine-pitch COB screens give spot-on colors and low upkeep—great for studio walls or watch centers.

Event LED Displays (e.g., concerts, exhibitions)

Stage events need tough, easy-to-move options. GOB fits the bill here. UHLED’s shelf display LED screens with GOB surface treatment offer fast setup tools, smooth joins, and an IP65+ water rating. The tough build cuts break during live gigs or fairs.

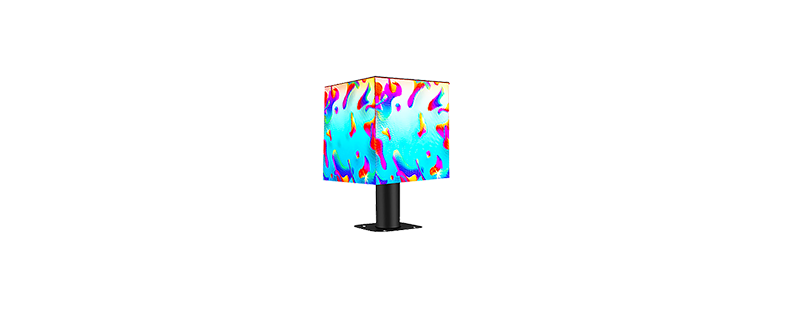

Retail Store LED Displays (e.g., window signage, product walls)

In upscale shops chasing clean looks, COB balances style and staying power. For busy spots with lots of foot traffic, GOB guards against dings or grime. UHLED’s indoor fixed LED screens work with both, based on what you need. A high-end boutique might use COB for crisp product shots, while a mall kiosk picks GOB for daily handling.

Outdoor Fixed Installations (e.g., billboards, public signage)

Outside spots deal with rain, dirt, and sun. UHLED’s outdoor GOB displays have IP66 water-tight cases for steady running in bad weather. They handle rain, snow, dust, and more without skipping a beat. GOB proves a smart pick for value and fixes long-term, like on a city billboard facing storms year-round.

UHLED’s Approach to Advanced Packaging Technologies

在 UHLED, we provide a wide range of LED display items for inside and outside jobs using GOB and COB. Our fine pitch indoor displays use COB to bring smooth sights with super-high detail and few breakdowns. For event or rough use, some of our screens apply GOB for better bump resistance and water shield.

UHLED runs as a tech firm blending design, making, and selling. We handle over 120,000 square meters of yearly output. Certifications like CE, FCC, ETL, and RoHS keep our quality tight across lines. Our 5-year promise, plus round-the-clock tech help and far-off fixes, gives global customers real ease.

Conclusion: Making the Right Choice for Your Project Needs

Picking GOB or COB hinges on your setup. COB delivers top detail, heat handling, and clean looks for inside work. GOB stands out in strength, bend, and fix ease—mainly for outside or rental spots.

As a worldwide source of fresh LED fixtures, UHLED sticks to high-quality displays matched to your business. Be it a watch post or a big outside push, our crew offers custom advice and aid at each step. We’ve helped firms from small shops to global events, drawing on years of field know-how to match tech to needs.

常见问题解答

Q: What is the main difference between GOB and COB technology?

A: The main difference lies in their packaging approach—COB uses direct chip bonding on the board while GOB applies a protective glue layer over standard SMDs. This affects performance in areas like impact resistance, heat dissipation, and repairability.

Q: Which is better for fine pitch LED displays?

A: COB technology is generally more suitable for fine pitch indoor displays due to its seamless surface, better thermal management, and higher pixel density.

Q: Is GOB or COB better for outdoor use?

A: GOB is often preferred outdoors because its glue layer provides excellent waterproofing and impact resistance. However, environmental conditions should be considered when choosing.

Q: Which technology offers a wider viewing angle?

A: COB typically offers a wider viewing angle with more consistent color reproduction across different perspectives.